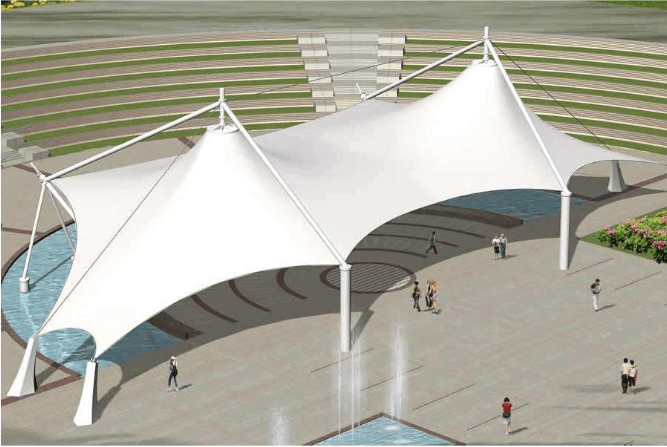

Crafting Excellence: The Art of Tensile Structure Manufacturing

Tensile structures have become synonymous with modern architecture, offering striking aesthetics and unparalleled functionality. But behind every iconic tensile structure is a manufacturing process that demands precision, expertise, and a dedication to quality. Join us as we explore the art of tensile structure manufacturing and how Global Tensile Structure crafts excellence in every project.

Innovative Design and Engineering

The journey of a tensile structure begins with innovative design and engineering. At Global Tensile Structure, our team of designers and engineers works tirelessly to transform concepts into reality. We leverage cutting-edge technology and advanced software to create designs that push the boundaries of creativity and functionality. From initial sketches to detailed 3D models, every aspect of the design is meticulously crafted to meet the unique requirements of each project.

Quality Materials and Fabrication

Central to the success of any tensile structure is the quality of materials used in its fabrication. At Global Tensile Structure, we source only the finest materials from trusted suppliers. Our tensile membranes are made from high-performance fabrics that offer durability, weather resistance, and aesthetic appeal. These materials undergo rigorous testing to ensure they meet our strict quality standards before being used in fabrication.

Our fabrication process is a blend of art and science, combining state-of-the-art machinery with skilled craftsmanship. Whether it's cutting, welding, or sewing, every step of the fabrication process is carried out with precision and attention to detail. Our experienced team of fabricators brings years of expertise to every project, ensuring that each component is crafted to perfection.

Advanced Manufacturing Techniques

Tensile structure manufacturing requires advanced techniques and technologies to achieve the desired results. At Global Tensile Structure, we utilize a range of cutting-edge manufacturing processes to bring our designs to life. From computer-controlled cutting machines to automated welding systems, we leverage technology to streamline production and maintain consistency and quality.

Customization and Flexibility

One of the key advantages of working with Global Tensile Structure is our ability to offer customization and flexibility. We understand that every project is unique, and we pride ourselves on our ability to tailor our manufacturing process to meet the specific needs of our clients. Whether it's a small-scale canopy or a large-scale stadium roof, we have the expertise and resources to deliver.

Quality Control and Assurance

Quality control is paramount in tensile structure manufacturing, and we take it very seriously at Global Tensile Structure. Every component undergoes rigorous quality inspections throughout the manufacturing process to ensure it meets our standards. From material testing to weld inspections, we leave no stone unturned in our quest for excellence. Our commitment to quality is unwavering, and it is evident in every structure we deliver.

Conclusion

At Global Tensile Structure, manufacturing isn't just about building structures—it's about crafting excellence. From innovative design and quality materials to advanced manufacturing techniques and stringent quality control, every aspect of our process is focused on delivering the highest standards of quality and craftsmanship. Join us on our journey as we continue to push the boundaries of what's possible in tensile structure manufacturing.

-1737565916776.jpeg)